Seçilenleri karşılaştır

Menüyü Kapat

Kategoriler

- Anasayfa

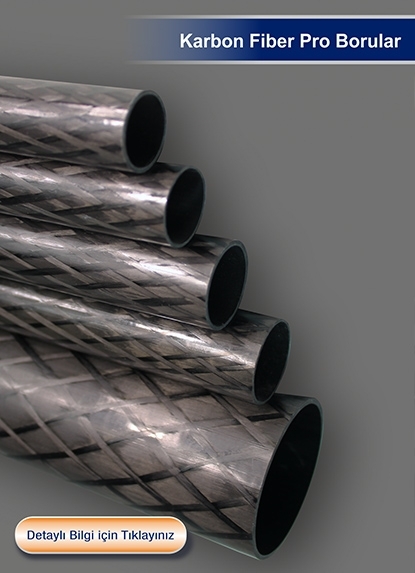

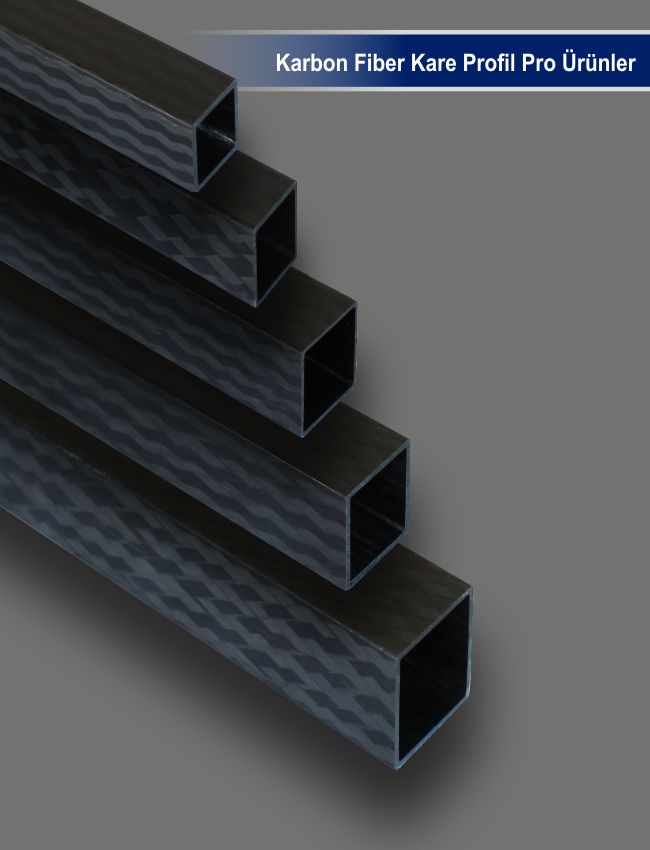

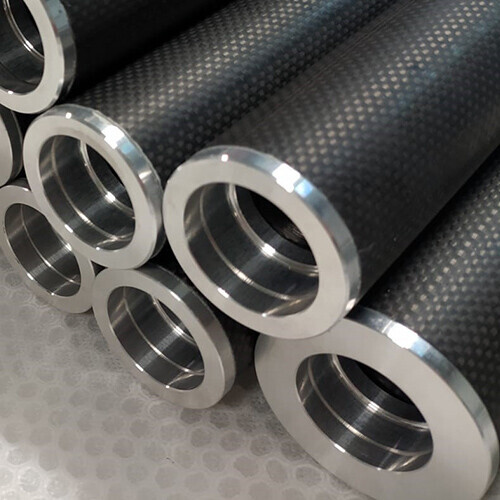

- Karbon Borular

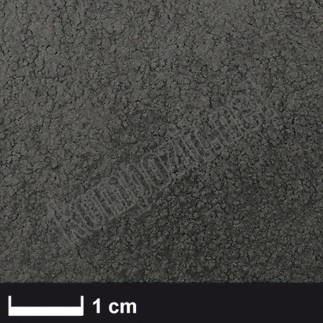

- Karbon Takviyeler

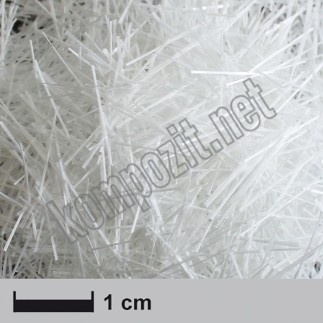

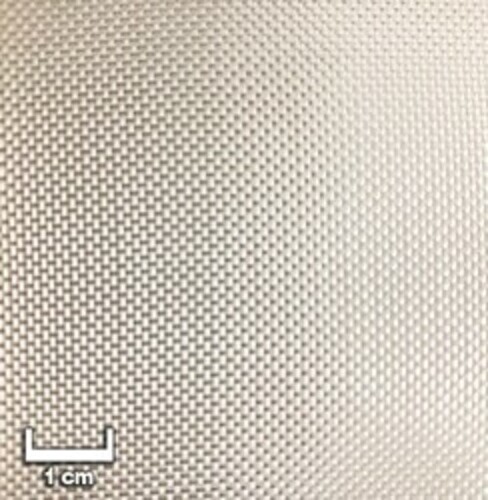

- Cam Ürünler

- Cam Takviyeler

- Hibrit Takviyeler

- Aramid Takviyeler

- Karbon Şeritler

- Karbon Çubuklar

- Karbon Plakalar

-

Sarf Malzemeler

- İnfüzyon Sarf Malzemeleri

- Vakum Sarf Malzemeleri

- Tümünü Gör »

- Epoksiler

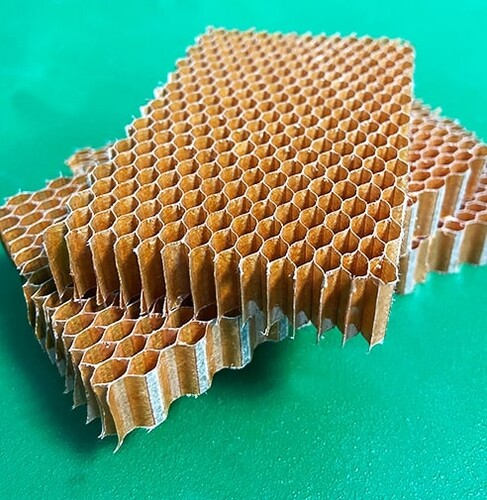

- Nüveler

- Kitler

- Alet Ekipmanlar

- Yapıştırıcılar